Posted: Sun Sep 27, 2009 9:44 am

Got a little more done on the English wheel yesterday. A guy I talked to on the phone that builds E-Wheels said if I build one it needs to be very sturdy & needs a lot of adjustment built in. So, this is what I came up with for the top anvil. It's a little more complicated than it needs to be, but I had a couple old air actuated hydraulic cylinders laying around that I wanted to make use of. I got them for free probably about 30 years ago and finally decided it's time to use what's left of them. I found one of the cylinder housings was corroded through but the ram was still good & that's what I needed for the anvil adjuster. Too bad they are shot, the cylinders are all aluminum (except for the ram).

Anyway here's the deal. I cut a couple sleeves out of aluminum round stock for the rams.

Cut a couple supports for the sleeves on the CNC

Parts pressed together. I didn't want the anvil assembly to rely on threads cut in aluminum, so I made this little pocket to hold a nut for the 3/4" ready rod that will be the adjusting screw.

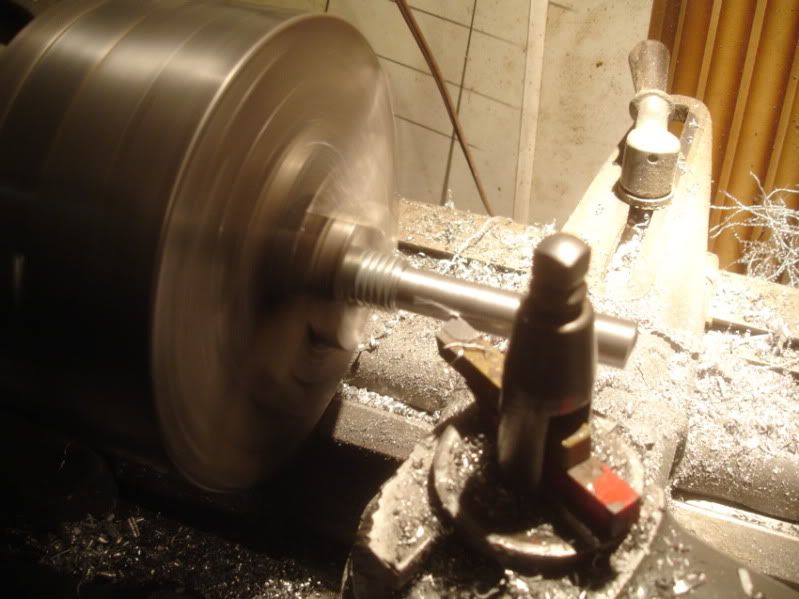

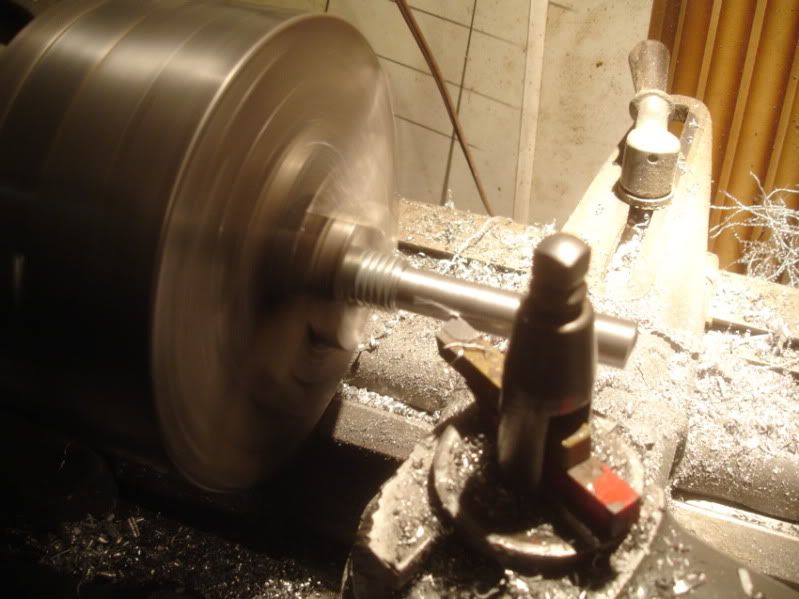

Turning part of the ready rod down to 5/8'' to make an adjuster out of it.

Anyway here's the deal. I cut a couple sleeves out of aluminum round stock for the rams.

Cut a couple supports for the sleeves on the CNC

Parts pressed together. I didn't want the anvil assembly to rely on threads cut in aluminum, so I made this little pocket to hold a nut for the 3/4" ready rod that will be the adjusting screw.

Turning part of the ready rod down to 5/8'' to make an adjuster out of it.