Page 118 of 146

Re: "Z" progress.

Posted: Sat Apr 17, 2010 11:11 pm

by Mrs. Stimpy

thats pretty good , a little hammering and dollying and it will look perfect

Re: "Z" progress.

Posted: Sat Apr 24, 2010 8:06 pm

by pro70z28

Re: "Z" progress.

Posted: Sat Apr 24, 2010 8:10 pm

by pro70z28

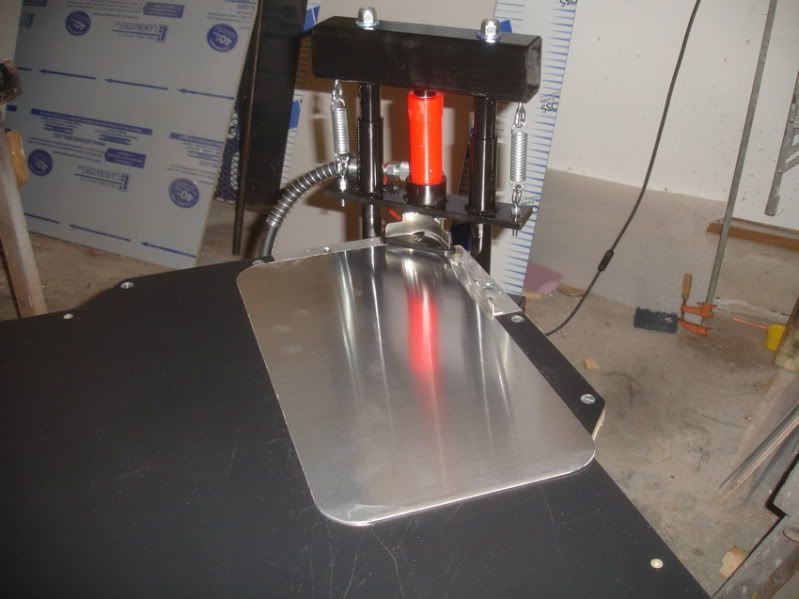

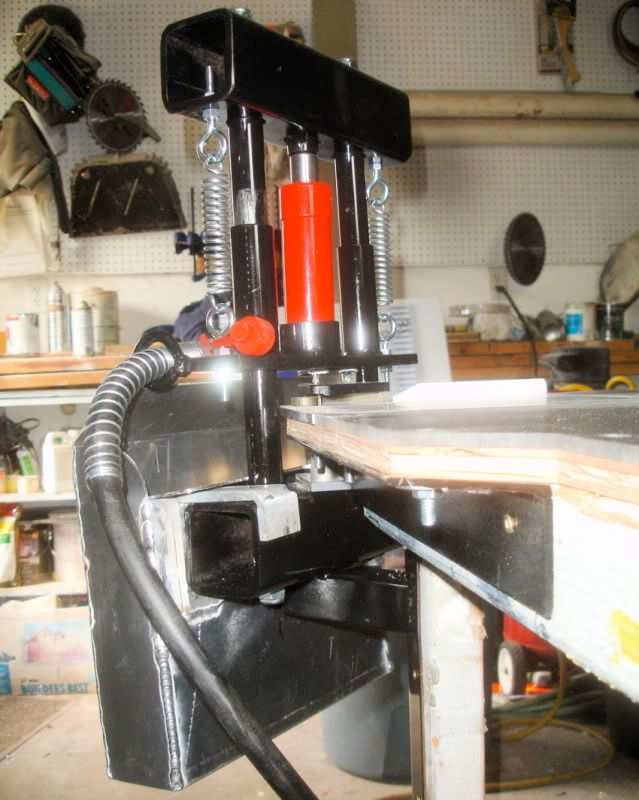

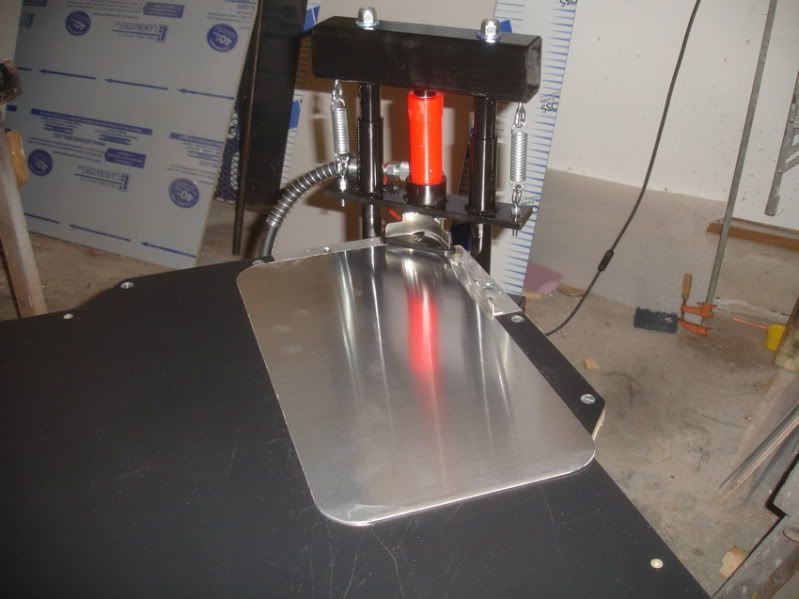

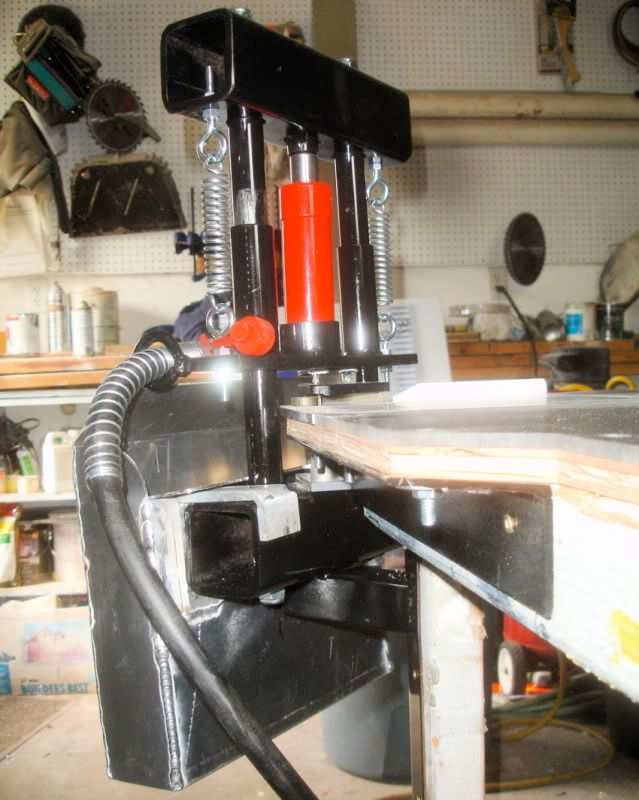

Tore it all apart & sent it off to the paint shop for a deluxe black rattle can paint job.

All back together.

Gave it a try.......works....... This will be much faster.

Re: "Z" progress.

Posted: Sun Apr 25, 2010 1:25 pm

by Billy Mac

Does that leave a sharp edge on the underside of the corner Gary? (been doin my corners with tin snips

)

Re: "Z" progress.

Posted: Sun Apr 25, 2010 1:51 pm

by pro70z28

I've been using an electric shear.

Nope the edge is nice N' smooth. I don't know if that will continue when the die gets a few miles on it, but it's goota' to go for now.

Re: "Z" progress.

Posted: Sun Apr 25, 2010 2:10 pm

by Billy Mac

How heavy a gauge material will that contraption handle?? The "majority " of what I deal with is .o40 thou. unless I'm doin a wing/spoiler for someone....I do the spill plates out of 1/8th inch and the main item out of .090. I've been using my jig saw and a squirt bottle of water to cut the shape on the spill plates. (the water keeps the blade from heating up and clogging the teeth with melted aluminum

)

Re: "Z" progress.

Posted: Sun Apr 25, 2010 2:24 pm

by pro70z28

It's supposed to be good to 1/8''. I'll be using it mostly for .080 & 1/8" aluma panel.

Re: "Z" progress.

Posted: Sun Apr 25, 2010 2:30 pm

by Billy Mac

Cool...Power tools and equipment sure do help speed things up

Re: "Z" progress.

Posted: Sun Apr 25, 2010 5:22 pm

by pro70z28

Made a catch can so I wouldn't have little corners layin' all over the shop floor. (and gettin' them stuck in my shoe.....and taking them in the house........and.......

)

Re: "Z" progress.

Posted: Sun Apr 25, 2010 7:27 pm

by Rapid Randy Baker

Landlord, that is some pretty neat stuff you build and work with.